The standard bolt making machine produced by Ronen® runs smoothly, can handle materials of different thicknesses, and takes up little space. It is easy to operate and many small workshops choose it.If you plan to produce high quality foundation bolts on a regular basis,please contact us to provide you with the most cost-effective quotation.

The standard bolt making machine is a specialized equipment designed for manufacturing threaded anchor bolts. It is mainly composed of the feeding system, heating system, forming system, thread processing system and cutting system. It can produce foot bolts of different specifications.

The feeding system of the standard bolt making machine automatically feeds steel bars or round steel into the machine; the heating system heats the steel to the appropriate temperature to facilitate subsequent processing; the forming system uses molds to extrude the steel into the shape of the head of the anchor bolt; the thread processing system machine-cut the threads on the bolt shaft, usually through methods of threading or rolling; the cutting system cuts the processed bolts from the steel.

Operating the machine involves multiple integrated stations. First, the unwinding machine feeds the steel bar into the straightening machine. Then, the precise shearing machine cuts the steel bar into the bolt length as programmed. The cut blanks then move to the forging die, where they are formed into the required head shape under high pressure. Finally, the bolt rod advances to the thread processing device to produce the precise thread shape.

The standard bolt making machine is used for processing steel wire rods, and its diameter is typically suitable for foundation anchors. The powerful upsetting machine applies tremendous pressure to the end of the steel wire rod after cutting, forming a load-bearing head without heating the metal, thereby maintaining its strength. This forging ability is crucial for creating a sturdy head.

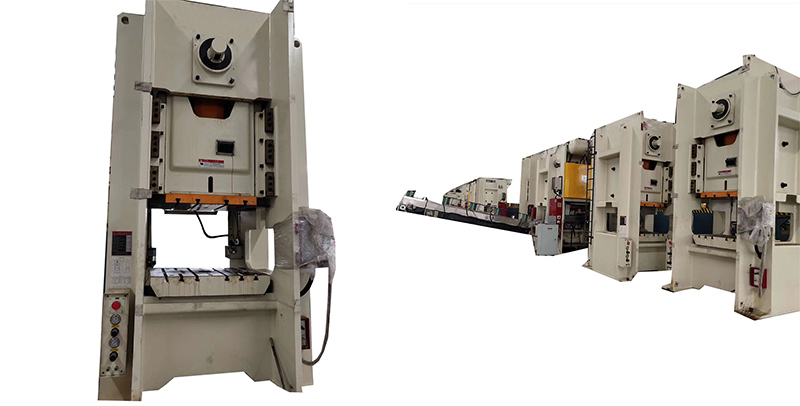

|

Punch Shape |

Tiltable Punch |

Slider Movement |

Double Action |

|

Slider Drive Mechanism |

Rack Press |

Controlling Mode |

CNC |

|

Automatic Grade |

Automatic |

Power Source |

Hydraulic Pressure |

|

Precision |

Normal Precision |

Certifcation |

ISO 9001 |

|

Condition |

New |

Transport Package |

Export Packaging |

|

Trademark |

RONEN |

Origin |

Hebei, China |

|

Production Capacity |

10 Set/Sets Per Month |

|

|

The heating system of the standard bolt making machine is very powerful. It can evenly heat the steel to the appropriate temperature, so that the steel is less likely to crack during the forming process. The mold of the forming system has high precision, resulting in standard bolt head shapes and small size errors. The threaded processing system produces clear threads that fit well with the nuts, and the bolts are less likely to loosen after being tightened. Moreover, the production process of this machine is very stable. It can work continuously for a long time without any instability in bolt quality.