If you are interested in purchasing a fully automatic screw making machine, Ronen® factory is sure to meet your needs. Our equipment is capable of producing screws with high precision and in large quantities. You can meet customer demands more efficiently and produce screws at a lower unit cost.

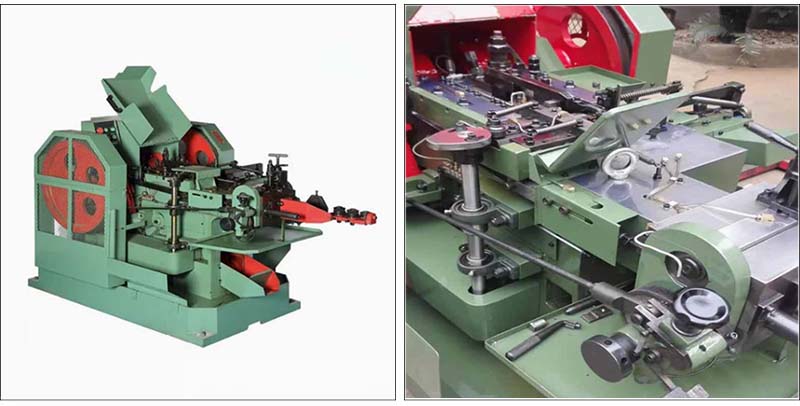

The Fully automatic screw making machine can continuously complete the processing from wires to screws. Feeding the rolled steel, straightening/cutting the blank, forming head and rolling the thread, all operations do not require manual operation. You will enjoy excellent after-sales service.

Feed the steel/stainless steel wire coils into the screw making machine. It can handle all processes: uncoiling, straightening, fixed-length cutting, heading and threading. Please note that maintaining a consistent wire diameter is of vital importance. When operating at high speed, changes in wire diameter can cause blockage.

The Fully automatic screw making machine gives priority to output. The small screws are expected to be 400 to 800 per minute. However, the speed requires perfect calibration. A 0.1-millimeter tool offset could damage 1,000 screws before an emergency stop. It will wear out the punch/die, so you need to have spare parts ready to facilitate your timely replacement and reduce the cost of downtime.

The screw making machine needs to take power and noise into consideration. Therefore, three-phase power supply, compressed air and ear muffs with a voltage of over 85dB are required. Leave a maintenance space of 1.5 meters. If heat accumulates, please add an exhaust fan, as overheating of electronic devices can cause random downtime.

At a rotational speed above 700 RPM, vibration can cause damage to the Fully automatic screw making machine. Fix it to the solid concrete with bolts. Use shock-absorbing pads when necessary. The bolt is loose? Head size deviation or premature bearing damage will occur very soon.