Ronen® factory direct sales of Cold Former. These machines are easy to operate and maintain, which can significantly enhance your productivity. Our prices are affordable and can save your costs. We offer a warranty service. If any problem occurs, we will do our best to repair it for you.

Cold Former is a heavy-duty press that can form metal parts at room temperature. It uses high pressure to press metal wires or bars into precision molds, thereby forming components such as nuts, bolts or special fasteners without cutting the material.

Cold forming machine mainly processes steel, stainless steel or non-ferrous metal wire coils. Its main advantages lie in speed and material efficiency. They can produce hundreds of parts per minute with very little waste because almost all the input materials are eventually formed into the final product. This makes them cost-effective when mass-producing standardized components, such as automotive fasteners or construction anchorages.

Running a Cold Former means you gotta keep an eye on three main things: how smoothly the wire's feeding in, whether there's enough lube flowing, and if all the tools are lined up right. The operator needs to listen for any weird noises – stuff like jams or tools acting up. It’s also smart to regularly pull a few parts off the line and check ’em for problems, like cracks or if they didn’t form completely. To dodge surprise downtime, do the basics: swap out worn punches and dies when needed, give the lube system a quick once-over, and check those key mechanical bits before they cause trouble.

The parts produced using screw cold heading machine have higher structural integrity. Cold working processes compress metal grains, enhance their hardness, and make them more stable and firm. This makes the fasteners more durable, that can withstand shearing or deformation under load. Stable mold quality and correct machine setup are crucial for maintaining dimensional accuracy and surface finish in high-speed production.

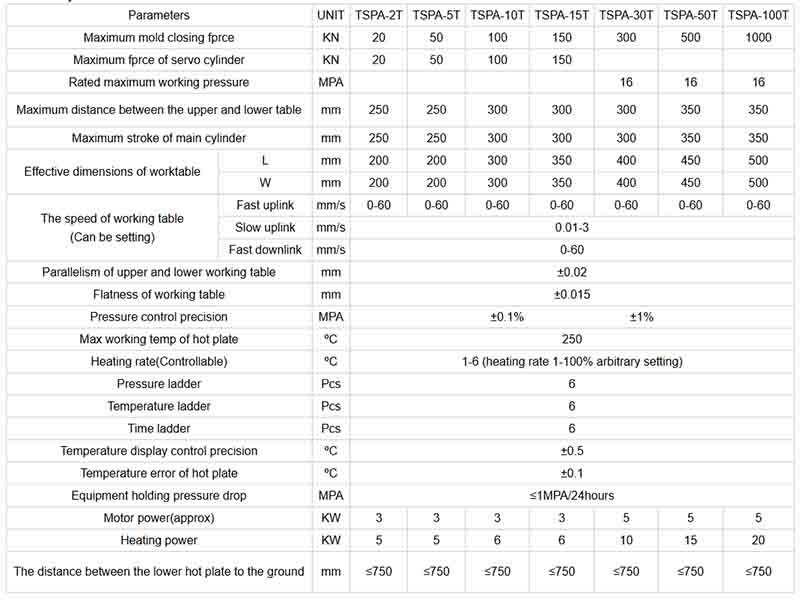

When purchasing Cold Former, please evaluate its production capacity (maximum part size/forming force), speed (strokes per minute), and compatibility with the required materials and tolerances. We will provide you with a sturdy rack, convenient technical support, readily available spare parts (especially punches/dies), and clear maintenance documentation.