The Ronen® cold forge header machine is easy to use and can effortlessly shape metal head components. It operates stably and does not require frequent shutdowns for adjustments. If you wish to increase the production of the head forging, you can choose the equipment from the Ronen® suppliers.

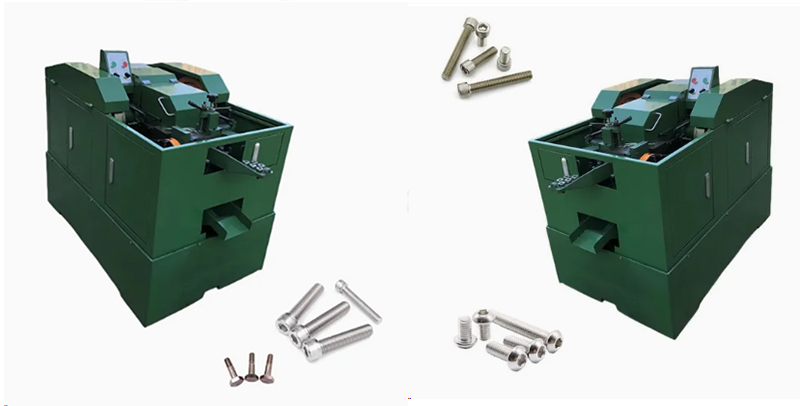

The cold forge header machine is a device specifically designed for shaping the heads of metal wire materials. It does not heat the metal; instead, it extrudes the wire through a mold at room temperature, pressing one end of the wire into various shapes such as round heads and countersunk heads.

Our factory produced cold forge header machine forms metal parts at room temperature using high pressure. It receives wire, straightens it, cuts it to the required length, and then uses punches to press the billets into the forming molds. They can manufacture the heads for fasteners such as bolts, screws or rivets. It is the main equipment for efficient mass production of many metal part heads.

Our machine starts with wire rods, which are usually steel coils but can also include other metals such as brass or aluminum. The unwinding machine feeds the wire into the straightening mechanism to remove any twists. Then, the precision cutting machine cuts the straightened wire into blanks of specific lengths. These uniformly sized blanks are the necessary starting point before entering the forging station for the actual upsetting process.

Cold forge header machine are designed for mass production. Their efficiency is measured by the number of parts they can produce per minute. This capacity depends on the number of dies, the complexity of the parts, and the materials used. Large, complex parts might not reach 100 per minute, while small, simple parts like nails and screws can produce over 400 per minute. Precisely because of its high production capacity, it's the preferred choice for a wide range of fasteners.

|

Model NO. |

4-20A |

Power Source |

Hydraulic Pressure |

|

Feature |

Automation |

Certification |

ISO 9001, CE |

|

Warranty |

24 Months |

Customized |

Customized |

|

Advantage |

Long Service Life |

Condition |

New |

|

Keywords |

Self Tapping Screw Machine |

Name |

Screw Making Machine |

|

Price |

Factory Direct Supply Price |

After Sales |

Provide Solution Within 24 Hours |

|

Usage |

to Make Different Screw |

Brand |

Ronen |

| Video Outgoing-inspection |

Provided |

Merit |

Run Steadily |

|

Raw Material |

Steel Low Carbon, Stainless |

Technical Merit |

Taiwan Technology |

|

Confrmation |

CE, ISO9001 |

Warranty Period |

1 Years |

|

Package |

Wooden Case or as Required |

Samples Service |

Free Samples |

|

Delivery Time |

in Stock, or 30-50 Working Days |

Transport Package |

Wood or as Required |

|

Specification |

Machine |

Trademark |

Ronen |

|

Origin |

Hebei |

Production Capacity |

30set/Month |

The cold forge header machine mainly consists of the feeding section, the cutting section, the head-forming section and the mold replacement system. The feeding section feeds the wire one by one into the machine. The cutting section cuts the wire to the preset length. When the mold in the head-forming section is pressed, the wire can be formed. The diameter of the wire that the machine can handle ranges from a few millimeters to several tens of millimeters, depending on the model of the machine.If you want more information about it, please contact Ronen® and our engineers will give you the most professional advice.